Cement-based, flexible, water absorption reduced, high abrasion resistance,

high-performance joint filler.

Cement-based, flexible, water absorption reduced, high abrasion resistance,

high-performance joint filler designed for filling joint gaps between 5-20

mm.

General Characteristics

• Excellent resistance to high temperatures up to 250°C

• High water repellency and flexible structure

• Excellent crack and shrinkage resistance.

| Appearance | Fine Powder |

|---|---|

| Color | Cardboard Box |

| Packaging | 20 kg Kraft |

| Standard | EN 13888-1 |

| Position No. | 10.300.2232 |

| Pallet Quantity | 60 Kraft, 1200 kg |

| Mixing Ratio | % 31 - 33 |

|---|---|

| Pot Life | ≤ 1 hour |

| Full Curing Time | ~ 12 hours |

| Time to Open Surface to Foot Traffic | ~ 24 - 48 saat |

| Application Temperature | (+5) - (+35) |

| Abrasion Resistance (mm³) | ≤ 1000 |

|---|---|

| Flexural Strength (N/mm²) | ≥ 2,50 N/mm² |

| Compressive Strength (N/mm²) | ≥ 15,00 N/mm² |

| Shrinkage (mm/m) | ≤ 3,00 |

| Water Absorption 30 minutes (g) | ≤ 2 |

| Water Absorption 240 minutes (g) | ≤ 5 |

| Fire Reaction Class | A1 |

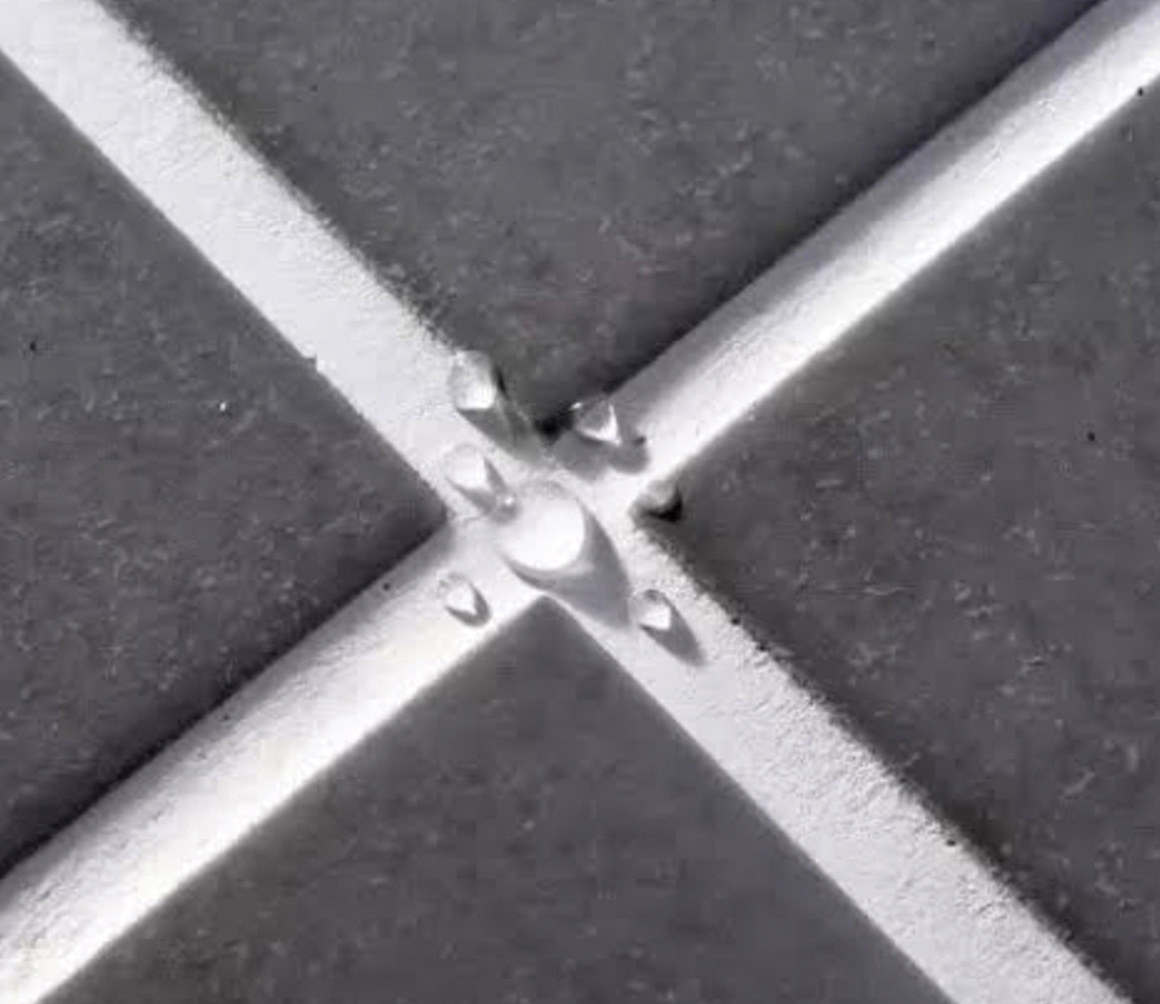

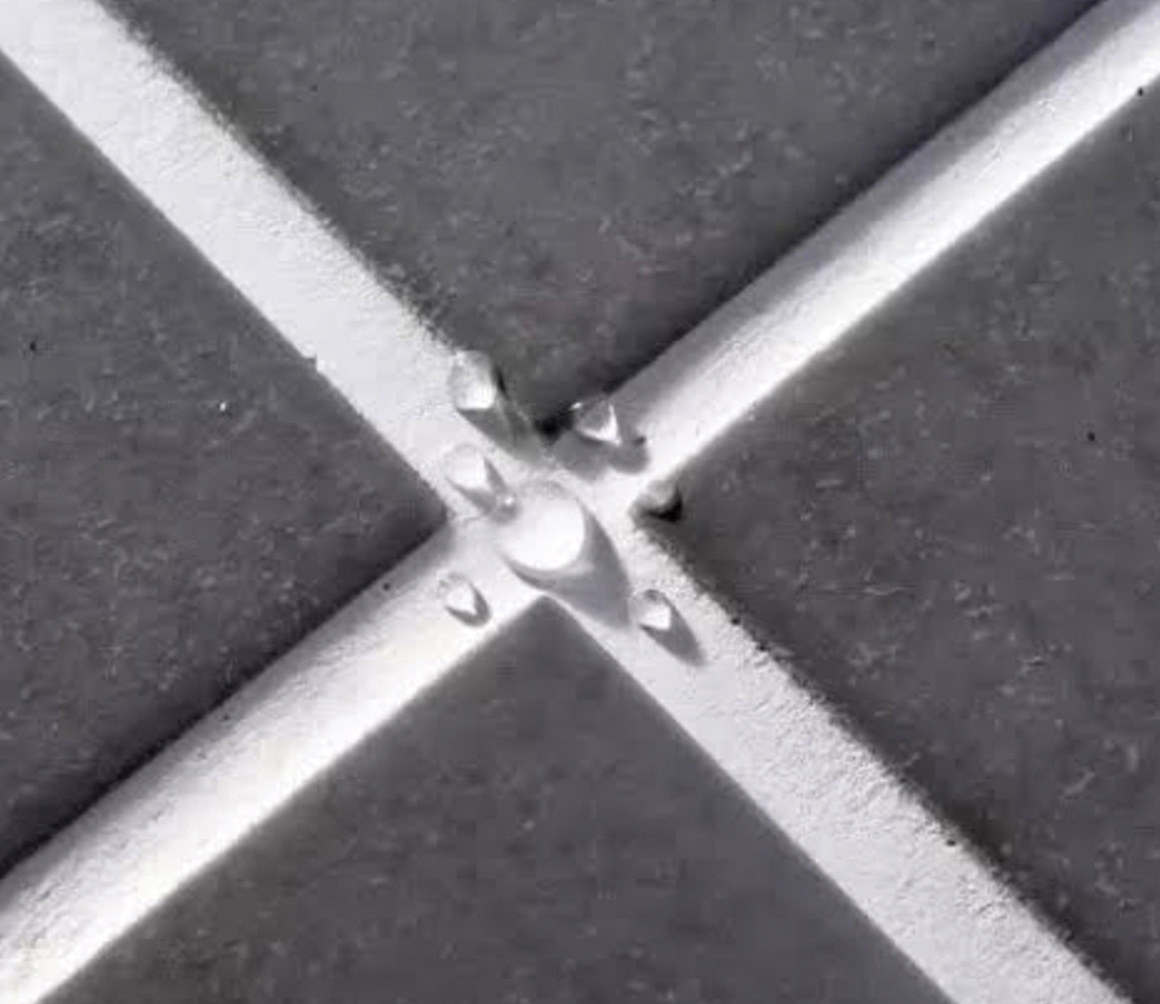

It is used for filling joint gaps of 5-20 mm in interior and exterior areas, on floors and walls, with materials such as ceramic, marble, natural stone, and glass mosaic. It is suitable for use in areas exposed to heavy traffic, requiring mechanical and chemical cleaning, such as industrial spaces, terraces, and balconies.

It should be stored in its unopened original packaging in a cool, dry place, protected from freezing. The appropriate storage temperature should be between +5°C and +25°C. The shelf life is 12 months from the production date when stored under proper conditions.

During application and mixing, contact with skin and eyes should be avoided. In case of contact, wash thoroughly with plenty of water. In case of eye contact, immediately rinse with water and seek medical attention. During use, gloves, protective clothing, mask, and goggles should be worn.

Approximately 6.20-6.60 liters of clean water should be slowly added to 20 kg of DRZ FLEX 5.20. It should be mixed with a low-speed mixer or trowel until a homogeneous mixture is obtained. No substances other than those specified in the application instructions should be added to the mixture. Adding too much or too little water can cause cracking, dusting, and color defects. The prepared mixture should be allowed to rest for 5-10 minutes for maturation. Before starting the application, it should be mixed again for 1-2 minutes. The mixture should be spread on the surface and filled into the joints with a rubber trowel using cross movements. Excess material should be removed from the surface. When the material in the joint loses its moisture and becomes matte, usually after 10-20 minutes, it should be cleaned with a damp sponge in circular motions. In cases of direct sunlight, wind, or unsuitable environmental conditions, especially on surfaces that have been exposed to the sun or have high absorbency, this time may be shortened. If the cleaning is done too early or with a very wet sponge, color variations may occur. The sponge should be cleaned frequently. Once the joint filler has dried enough to stay in the joint, any residue on the surface should be cleaned. The mixture should be used within 1 hour after preparation.