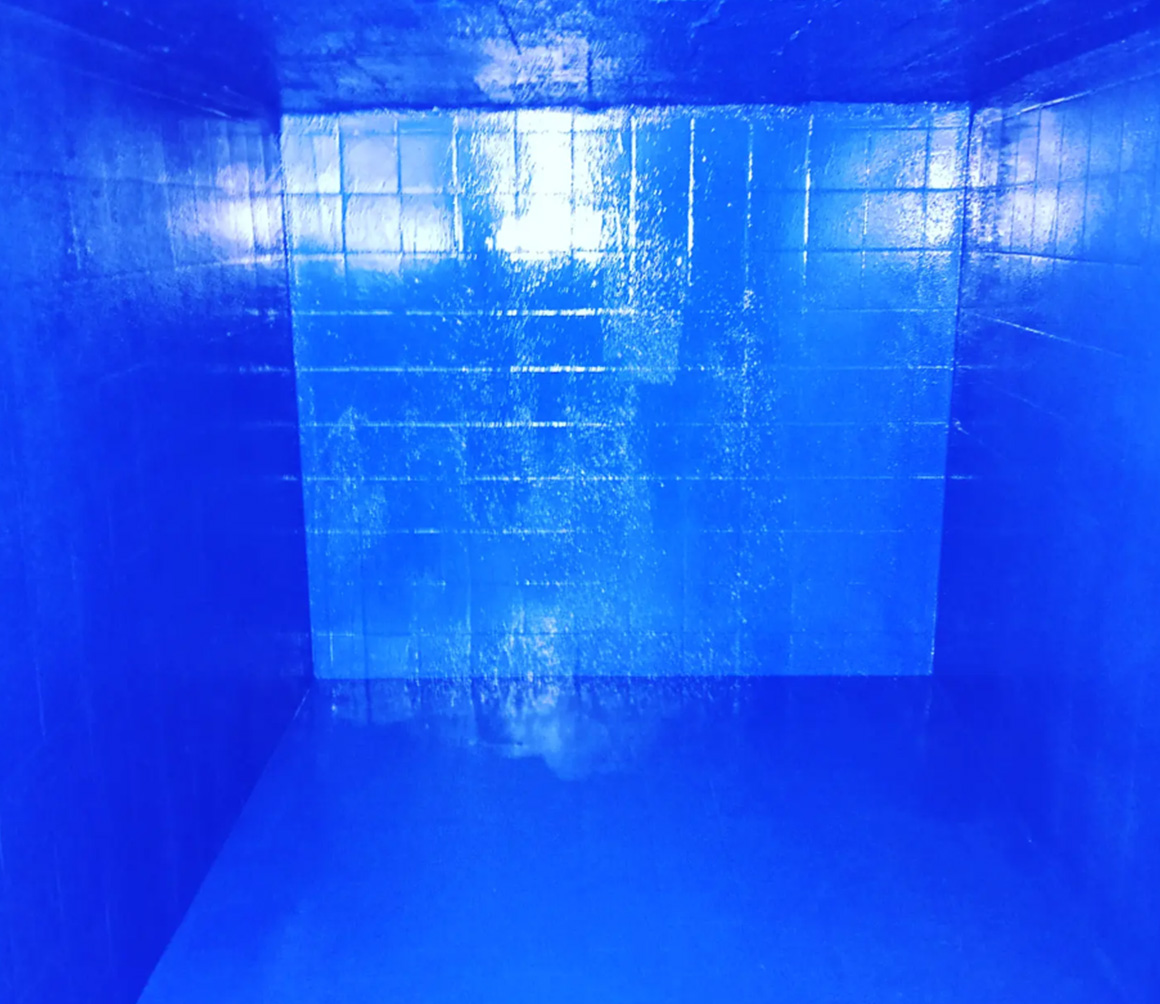

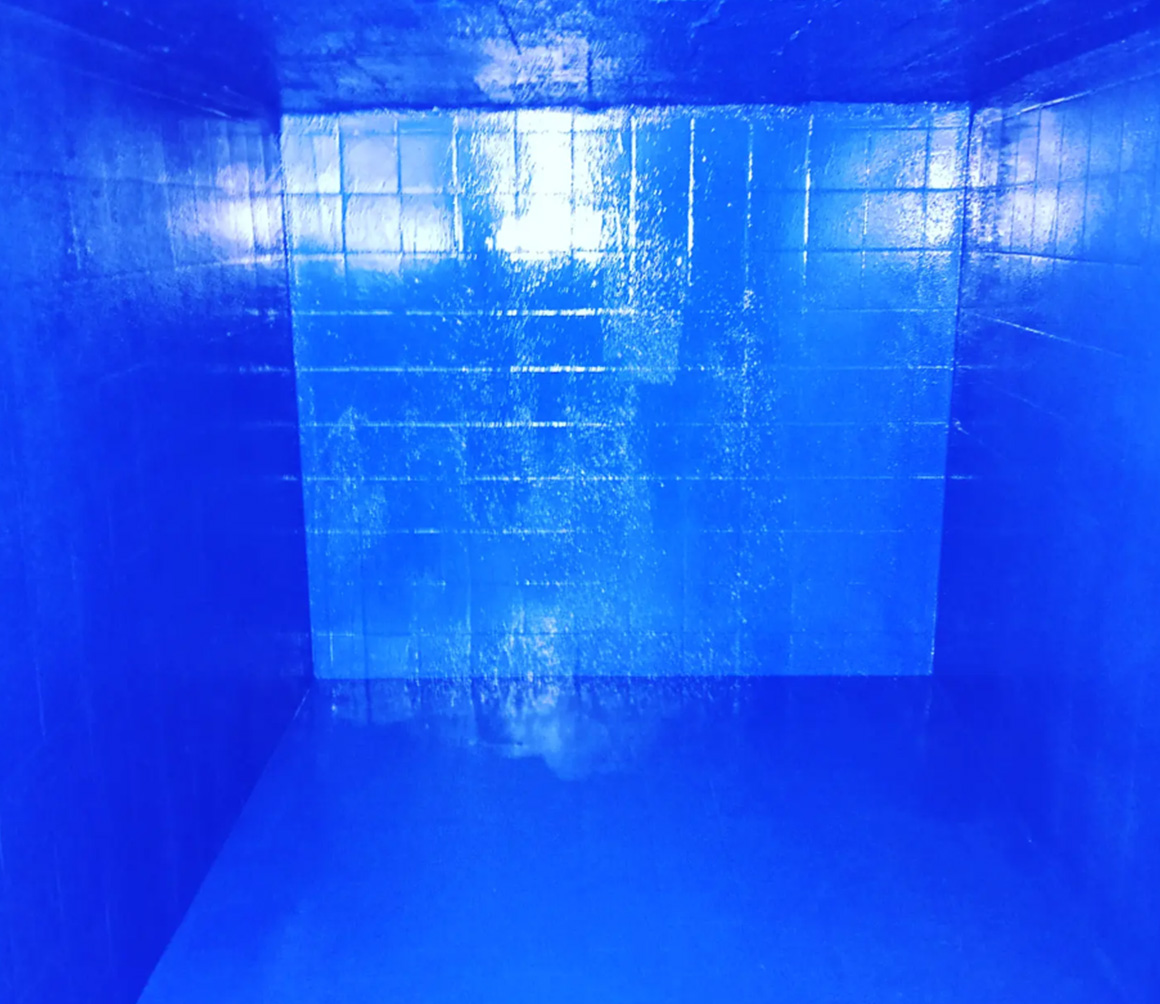

Polyurethane-based UV-resistant topcoat for insulation on swimming pools and water

tanks.

It is a solvent-free, two-component polyurethane-based liquid waterproofing material

designed for water tanks and swimming pools, used for waterproofing and protection

purposes

General Characteristics

It is solvent-free. It has excellent heat resistance performance within a

wide temperature range of -40°C to +90°C. It has excellent adhesion

properties. It can be easily applied in indoor spaces. It provides effective

resistance against chemicals. It is the most cost-effective solution for

water tanks in terms of cost and performance.

| Colors | Blue and White |

|---|---|

| Viscosity | 9000-10000 cp (A+B) |

| Density | 1,30 - 1,40 gr/cm3 (20°C 2 de) |

| Solid Content | %100 |

| Mixing Life | (+25°C): 30-35 min (at 25°C, 2 components) |

| Drying Time | 6 hours (at 25°C and 55% relative humidity) |

| Full Cure | 7 days |

|---|---|

| Intercoat Waiting Time | 8-24 hours (at 25°C and 55% relative humidity) |

| Service Temperature | 30°C to +80°C |

| Shore A Hardness | 50 |

| Elongation at Break | >%100 |

| Adhesion to Concrete | >2 N/mm2 |

It is used on metal and concrete tanks, tanks made of steel or other materials, water tanks and pools, surfaces in direct contact with water, and on polyurethane coatings.

For the first coat application, the minimum consumption is 0.75 - 0.90 kg/m². For the second coat application, the minimum consumption is 0.75 - 0.90 kg/m². The minimum total consumption is 1.50 - 1.80 kg/m². 4+1 kg and 20+5 kg packages. The material should be stored in a cool and dry place. When stored properly in its unopened original packaging, the material has a shelf life of 1 year.

It is flammable. Keep away from fire sources. Do not approach with cigarettes. The application areas should be well-ventilated, and during application, workwear, protective gloves, and masks should be used in compliance with occupational health and safety regulations. If it comes into contact with the skin, wash with soapy water. In case of ingestion, seek medical attention immediately. Wear gloves and goggles. Keep away from children.

The coating A+B components are mixed with a low-speed mixer for a few minutes until they are ready for use. The prepared mixture has a usage time of 30-35 minutes at +20°C, and this usage time varies inversely with temperature changes. To extend the pot life, the product can be poured onto the floor for application or transferred to a larger container. It should be applied in two coats by pouring onto the primed surface and using a roller or brush until the entire surface is covered. The second coat should be applied within a minimum of 8 hours and a maximum of 24 hours after the first coat. The product can be applied with a brush, roller, or spray. After use, clean the tools and equipment first with a cloth, then wipe with polyurethane thinner. (Rollers and brushes cannot be reused.)