Underlayment for waterproofing of screeds and ceramic coverings.

Underlayment for waterproofing of screeds and ceramic coatings.

General Characteristics

Quick application and ability to move to the next layer without waiting.

Waterproof. Crack bridging. Uniform thickness on all surfaces. Alkali

resistant. Easy to work with, easy to cut.

| Color | White background with gray raindrops |

|---|---|

| Membrane Width | Approx. 1.0 m |

| Longitudinal Break Elongation | Up to 99.8 N/15mm, 82.5% |

| Transversal Break Elongation | Up to 46.5 N/mm, 73.7% |

| Total Thickness | 0,51 mm |

| m² Gram | 220-240 g/m2 |

| Pressure Resistance | 3,0 bar |

| Crack Bridging | 0,4 mm |

|---|---|

| Adhesion | > 0,2 N/mm2 |

| SD-Value (Water Vapor Permeability Coefficient) | >85 m |

| Temperature Resistance | 35°C - +90°C |

| UV Resistance | >500 Hours |

| Packaging | 1 roll per box, in 10m or 30m rolls |

| Shelf Life and Storage | Store in dry conditions, protected from sunlight and frost, in unopened original packaging for approximately 24 months. |

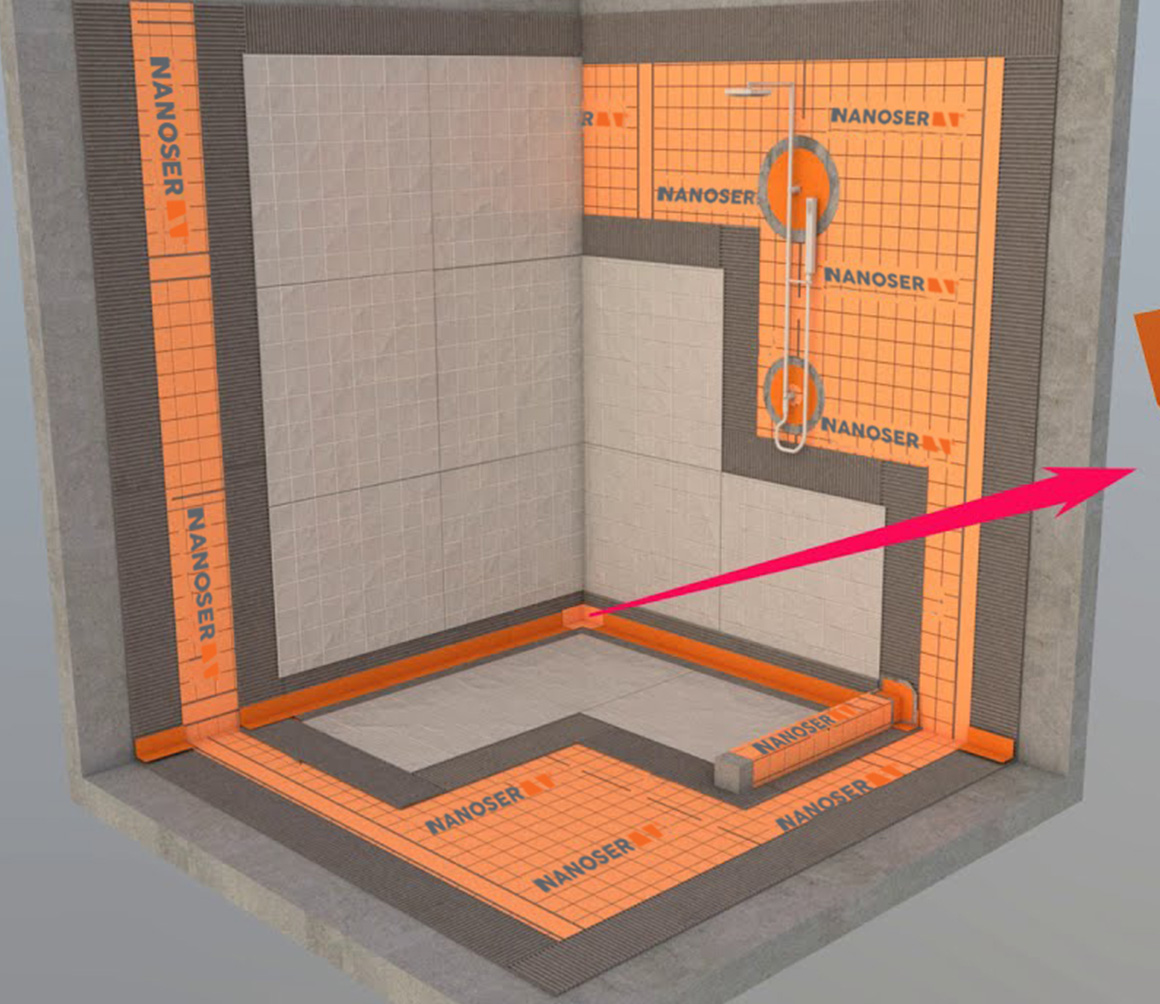

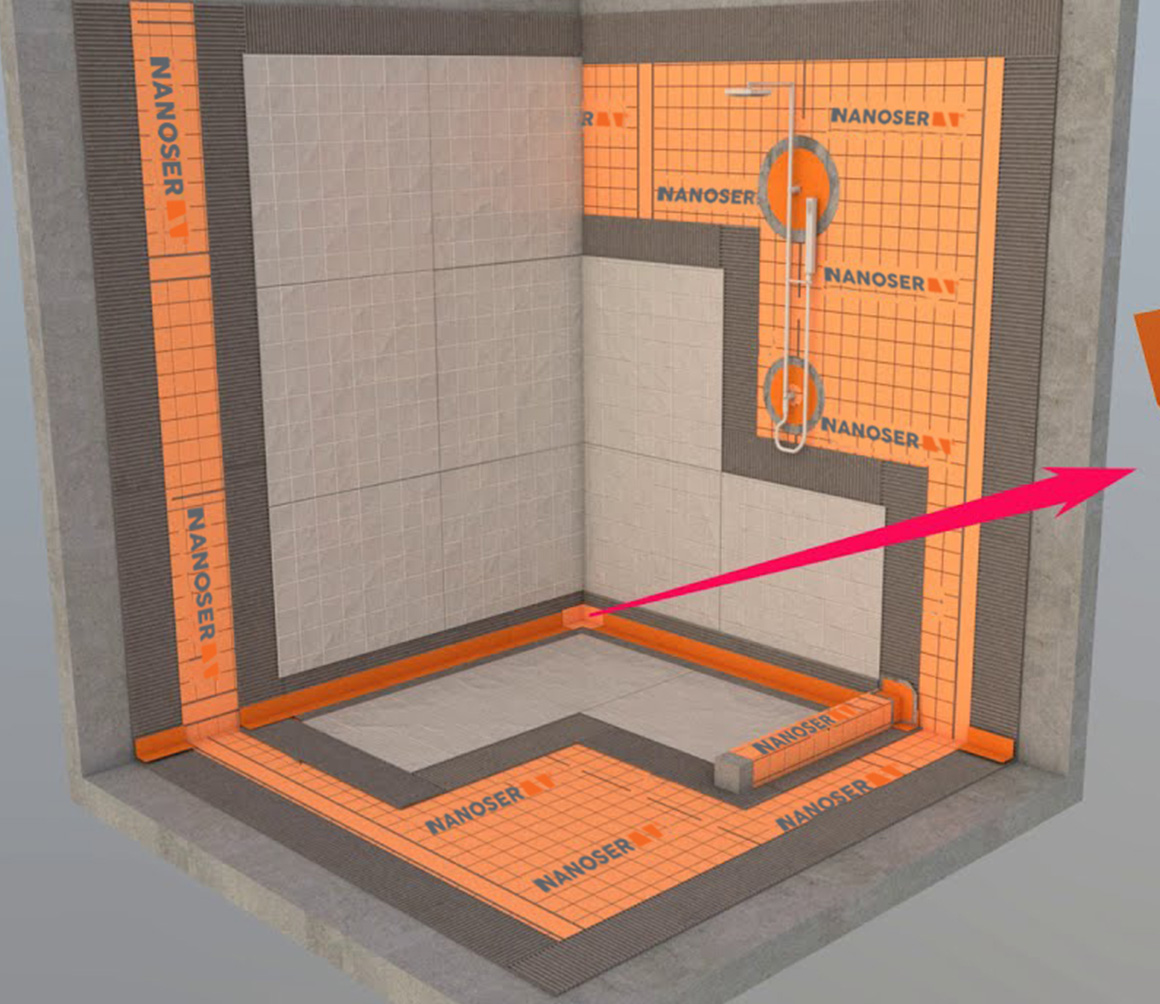

It is a waterproofing material applied under ceramic, tile, natural stone, etc. coatings on walls and floors, in both indoor and outdoor environments, thermal pools, and water reservoirs. It is used in areas where chemical emissions may occur, such as bathrooms, showers, hammams, pools, balconies, terraces, and cafeterias.

NANO TEX-60 Textile Membrane Waterproofing sheet is adhered using SY 550 G flex adhesive. Before applying the membrane, it is cut using scissors or a utility knife. After cutting, the SY 550 G is spread with a 3 mm notched trowel (4 mm for rough surfaces). The cut waterproofing membrane is then pressed onto the wet adhesive bed. The membrane is pressed down with the trowel to ensure there are no air bubbles underneath. It is recommended to pull the trowel from the center of the membrane towards the edges. The membranes should be applied with minimal spacing between them. At the joints, corners, transitions, and areas where sleeves are located, one side should overlap the other by at least 5 cm. In the system, high temperatures shorten the working and curing time, while low temperatures extend it. The application can be done between +5°C and 30°C.