Polyurethane-based, uv-resistant, highly elastic waterproofing material.

UV-resistant, polyurethane-based, single component, cold applied, gray, high elasticity

in liquid form, mechanically strong, walkable, waterproofing

coating.

General Characteristics

It can be used both under and over the coating. It is resistant to UV rays.

It is durable against light pedestrian traffic. It is resistant to continuous

water contact. It is a single-component product and easy to apply. It has

a high crack-bridging capacity. Seamless, continuous coating is applied.

It does not block vapor transmission. It is non-toxic and harmless. It is

resistant to alkalis and chemicals. It has high resistance to freezing.

| Material Structure | Polyurethane liquid |

|---|---|

| Color | Gray |

| Density | 1,35 gr/cm³ (20°C ve % 50 R.H.) |

| Hardness (Shore A) | 60 |

| Viscosity | 4000 - 6000 cP |

| Elongation | > %400 |

| Application Temperature | +5°C / + 35°C |

| Service Temperature | -30°C / + 80°C |

|---|---|

| First Drying | 4 - 6 Hours |

| Final Drying | 5 Day |

| Consumption | 1.50 - 2.00 kg/m2 (for 2 coat application) |

| The values above are given for +20°C and 50% relative humidity. Higher temperatures shorten the time, while lower temperatures extend it. |

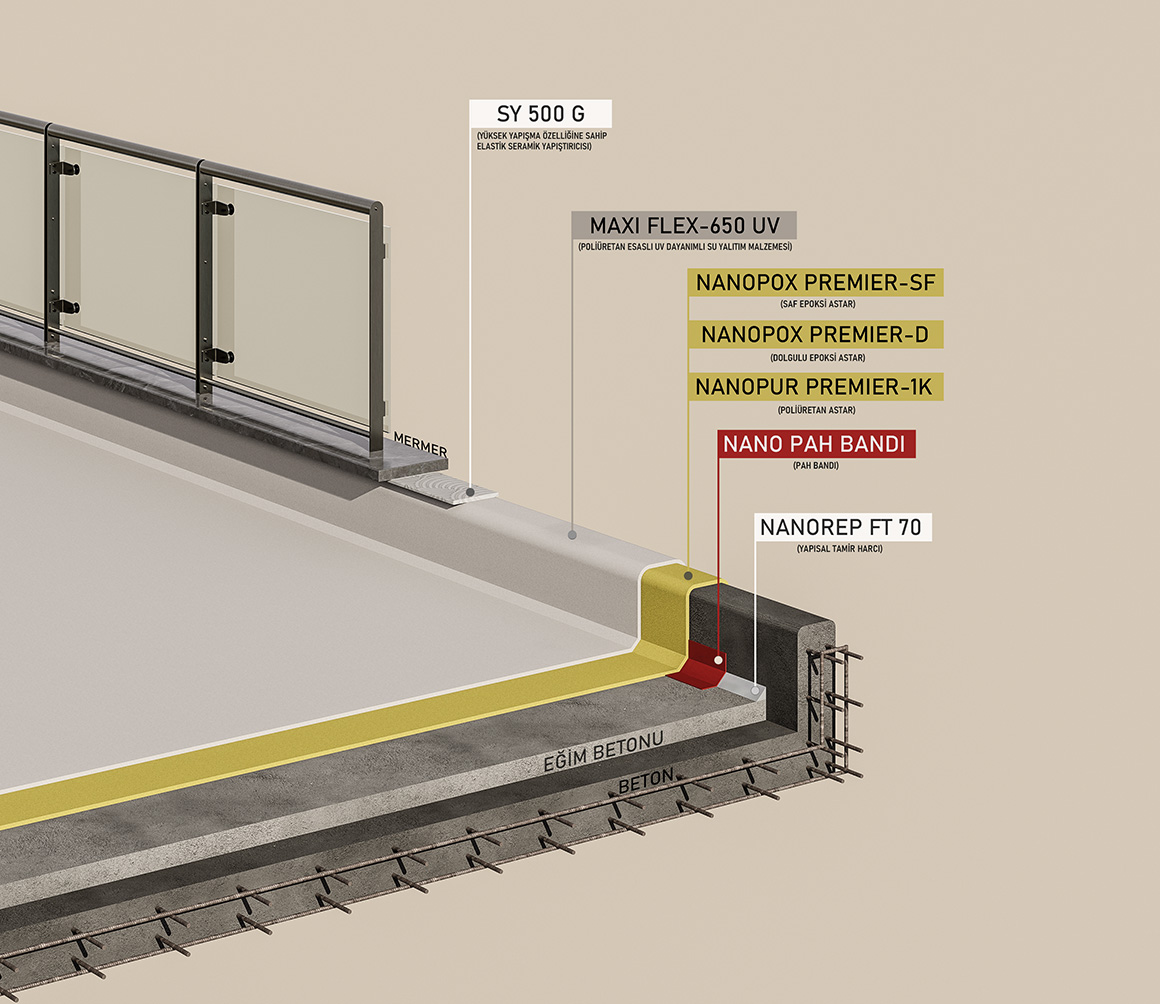

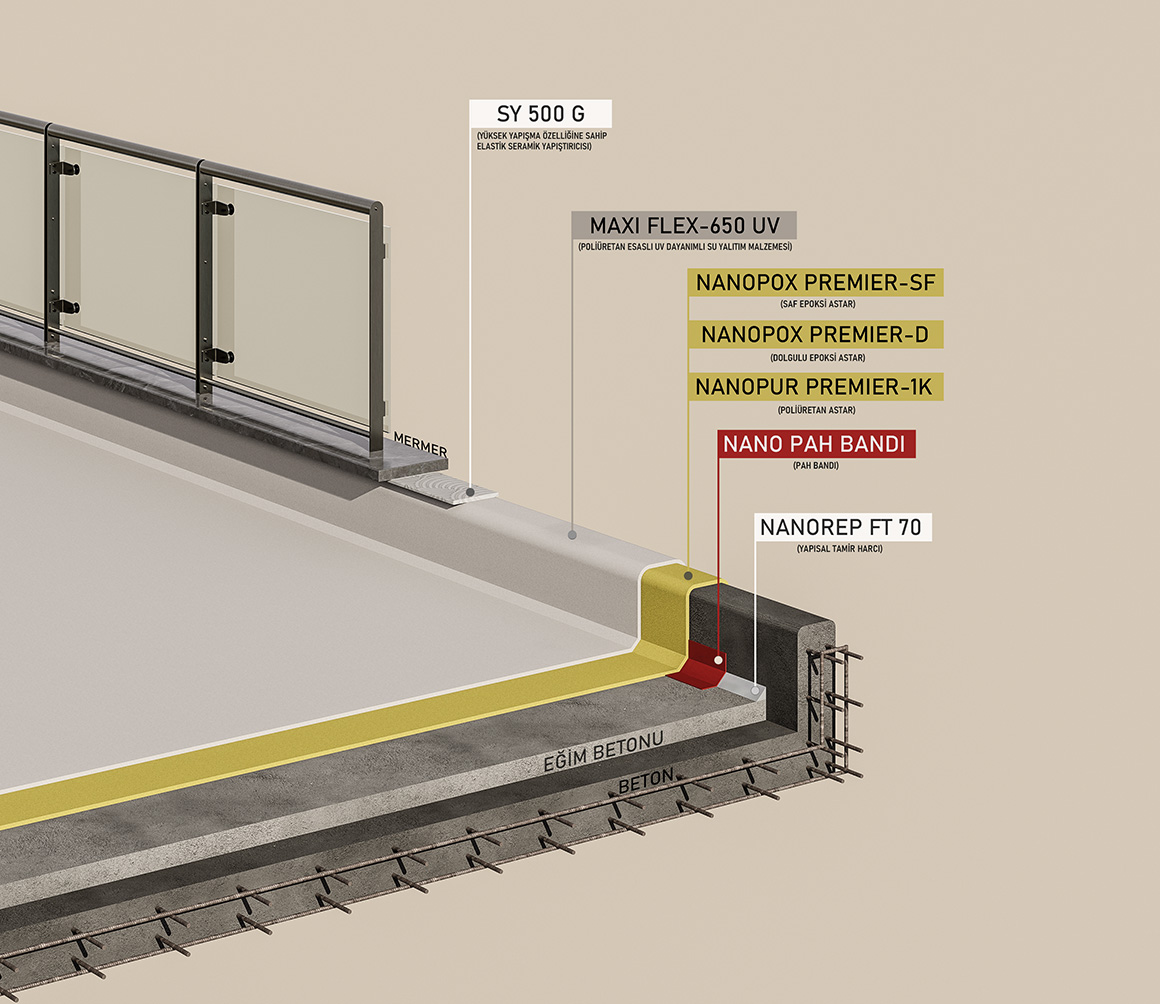

It is used on terraces, roofs, and balconies, in verandas, in hidden gutters, in wet areas such as bathrooms and kitchens, on metal surfaces, on mosaic surfaces, in water tanks, and in the insulation of water channels under coatings. It is also used in concrete structures such as bridges, viaducts, and tunnels.

25 kg Tin. When stored in its original packaging in a dry, protected, and ventilated environment between +10°C and +30°C, protected from sunlight, rain, and frost, its shelf life is 12 months from the date of production.

During application and mixing, contact with skin and eyes should be avoided. In case of contact, wash thoroughly with plenty of water. If contact with the eyes occurs, rinse immediately with plenty of water and seek medical help. During use, gloves, protective clothing, mask, and goggles should be worn.

The application surface must be cleaned of substances that prevent adhesion, such as dust, oil, tar, pitch, paint, silicone, curing agents, detergents, and form oils. Weak areas of the concrete should be repaired with NANOREP FT-70, poorly adhered plasters should be removed, and the surface should be made smooth and solid. Static cracks in the building should be repaired with latex-modified plaster or GFAST 725 mortar. Dynamic (moving) cracks should be filled with NP-U/025 polyurethane mastics, and appropriate chamfers should be made on vertical corners. Holes through which water enters should be sealed with JET PLUG. For priming, absorbent surfaces like concrete should be primed with NANOPUR PRIMER 1K, and non-absorbent surfaces like ceramic should be primed with WET 2C. The material should be mixed for at least 3 minutes with an appropriate mixer before use. Before application, the packaging should be opened, and the product should be mixed for at least 3 minutes with a low-speed mixer. The product should be poured onto the primed surface and applied in at least two coats using a roller or pull squeegee until the entire surface is covered. The second coat should be applied between 6 and 24 hours after the first coat. Application Conditions: The material should not be applied when the ground temperature is below +5°C or above +35°C. The material must be protected from rain, freezing, and direct sunlight within the first 24 hours after application. The application surface should not be wet at +20°C. For surfaces with high moisture, moisture-tolerant polyurethane or epoxy primers can be used before application. Consumption: 1.50 - 2.00 kg/m² (for two-coat application).