Polymer Emulsion, Cement - Based, Dual Component, Super Elastic Waterproofing Mortar.

General Characteristics

• Easy to prepare and apply.

• Bridges cracks thanks to its high flexibility.

• Provides fast and easy application on large surfaces.

• Has high durability.

• Offers a long working time.

• Provides high adhesion to the surface

| Adhesion Strength | (N/mm2) ≥ 1,00 |

|---|---|

| After Thermal Aging | (N/mm2) ≥ 1,00 |

| CO2 Permeability | Sd > 50 m |

| Capillary Water Absorption | (kg.m-2.dk-0,5) ≤ 0,10 |

| Crack Bridging | (mm) ≥ 0,75 |

| Fire Reaction Class | Bs1d0 |

| Consumption | 1 mm (kalınlık) 1,5 – 2,0 kg/m2 |

| Adhesion Strength | (N/mm2) ≥ 1,00 |

| After Thermal Aging | (N/mm2) ≥ 1,00 |

|---|---|

| CO2 Permeability | Sd > 50 m |

| Color | Gri |

| Density | 2,00±0,05 g/cm³ |

| Service Temperature | +-20°C ile +80°C |

| Application Temperature | +5°C ile +25°C |

| Full Curing | 7 günC |

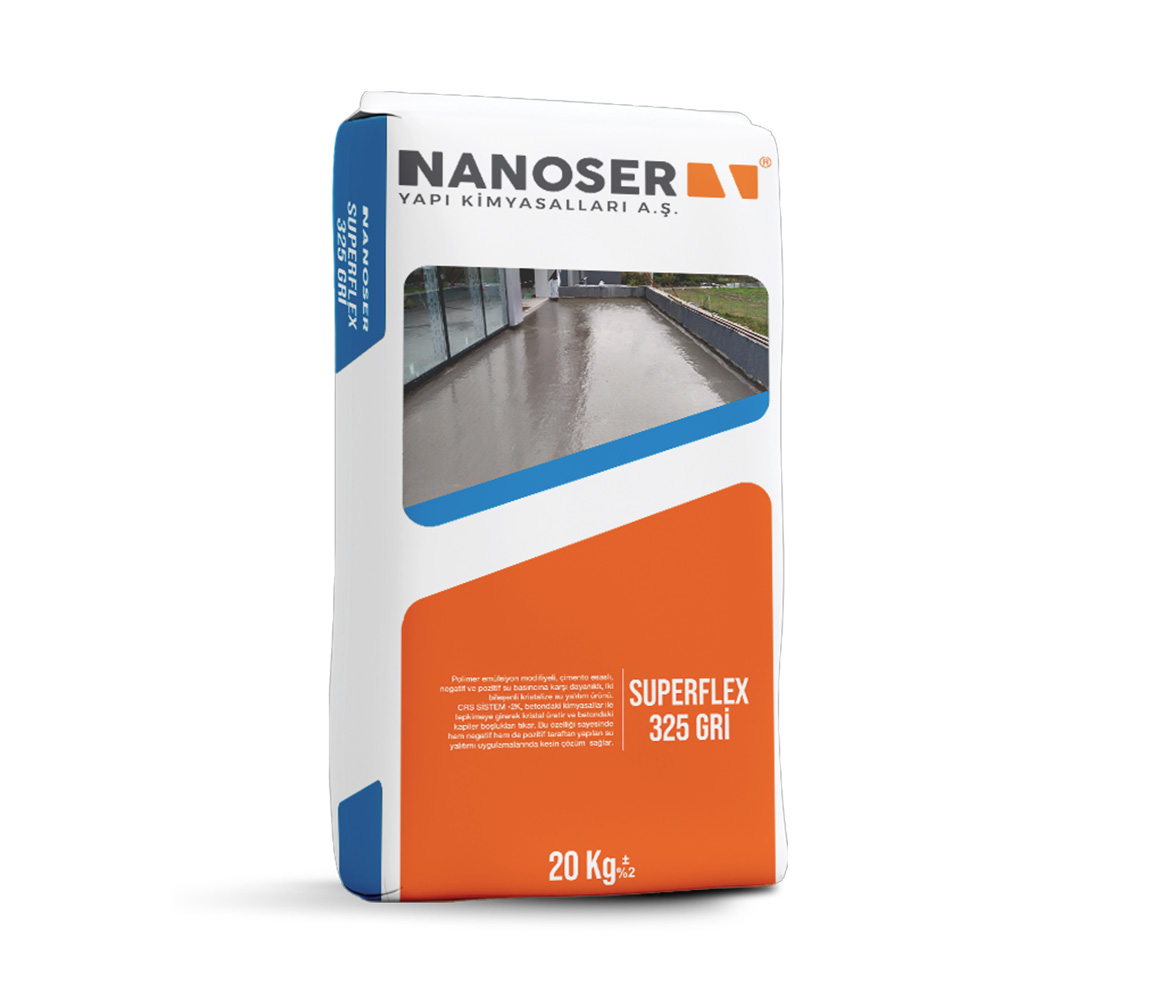

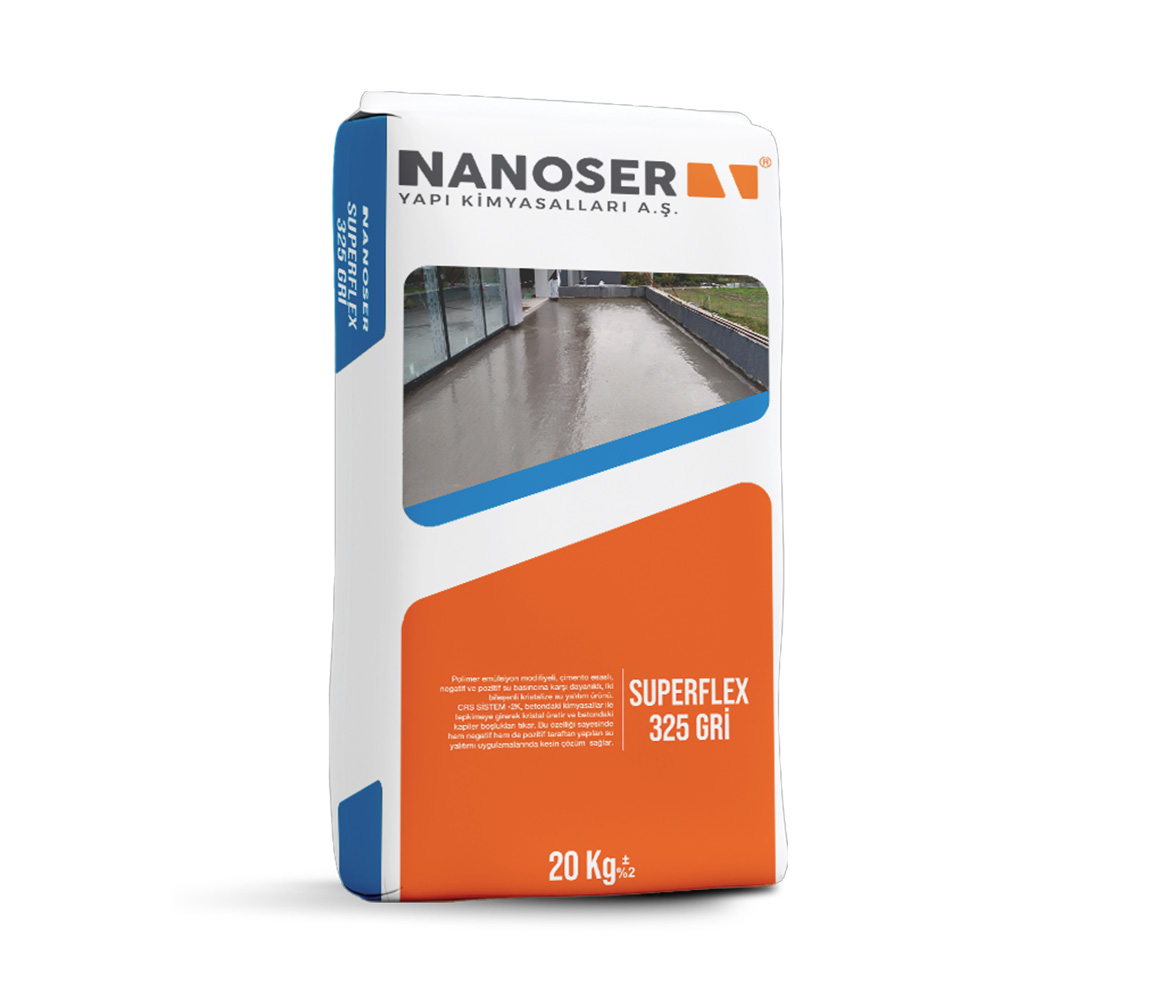

It is used as a waterproofing material in all types of buildings, both interior and exterior, in wet areas such as balconies, kitchens, toilets, and bathrooms, in high-performance foundation waterproofing, in vibration-prone areas, and in water tanks. Thanks to its super-elastic structure, it has a high crack-bridging ability. It can be safely applied on large terraces.

Packaging A: 20 kg Kraft B: 10 kg Drum Color: Gray It should be stored in a clean, dry, and moisture-free environment between +5°C and +35°C, avoiding direct sunlight. It must be protected from water, frost, and extreme weather conditions. It should be stacked up to a maximum of 10 layers. Provided that the specified storage conditions are followed, the shelf life is a maximum of 12 months from the production date.

During application and mixing, the material should be prevented from coming into contact with the skin and eyes. In case of contact, it should be washed thoroughly with plenty of water. If it comes into contact with the eyes, rinse immediately with plenty of water and seek medical assistance. During use, gloves, protective clothing, mask, and goggles should be worn.

The surface should be clean, damp, smooth, and solid. Significant defects and holes on the surface must be repaired with NANOREP FT70/30 series repair mortars at least 24 hours before applying SUPER FLEX 325. To maintain the continuity of the waterproofing, vertical and horizontal corners should be chamfered. Surfaces such as raw concrete or cement-based plaster should be wetted with clean water, and the surface should be kept damp until the water layer disappears. For porous surfaces, SUPERFLEX 325 GRAY should be used as a primer to balance the water absorption of the surface.