%2000 Elastic, bit root resistant, two-component bitumen-polyurethane waterproofing

material.

A bitumen-enriched, polyurethane-based, two-component, elastomeric, fast-curing liquid

membrane designed for waterproofing and protection purposes. It is suitable

for use on EPDM-bitumen membranes and asphalt surfaces. It adheres strongly to almost

every type of surface, forming a highly elastic film. It is used as a waterproofing

material against non-pressurized and pressurized water for the waterproofing of

foundations, basement walls, terrace roofs, balconies, parking lots, bridge decks, and

similar areas. It is also used in wet volume waterproofing and in areas where plant root

resistance is required. With its excellent consistency, it can be easily applied even

on complex details, creating a seamless waterproofing layer. It performs exceptionally

well on large terraces and deep foundations. It has high resistance to water pooling

and freezing. It is resistant to detergents, oils, seawater, and household chemicals. It

prevents water vapor and has crack-bridging properties. It adheres effectively to all

primed surfaces. If any damage occurs to the membrane, the affected area can be easily

identified and repaired quickly

General Characteristics

It can be used on all mineral-based surfaces, with high adhesion. It has

2000% elasticity. It is resistant to salt solutions and weak acids. It is resistant

to plant roots. It is resistant to freeze-thaw cycles. It creates a seamless,

monolithic waterproofing layer. It can be easily applied with a brush, trowel, or

spraying machine. It has low emission values and is environmentally friendly.

| Standard | EN 1504-2 |

|---|---|

| Product Class | Pr. 2,2 and 8,2 |

| Document Number | 2163-CPR-1091 |

| Product System | Bitumen - Polyurethane |

| Application Temperature | (+5) - (+35)0°C |

| Service Temperature | (-30) - (+90)0°C |

| Public Works Item No. | 10.300.2166 |

| Consumption | 1,80 – 2,20 kg/m2 |

| Number of Coats to Apply | 2 - 3 Coats |

| Intercoat Waiting Time | 12 - 24 hours |

|---|---|

| Opening to Light Pedestrian Traffic | ≈ 24 hours |

| Full Cure Time | ≈ 7 day |

| Hardness (Shore A) | 35 - 40 |

| Bond Strength to Concrete | ≥ 2,00 N/mm2 |

| Crack Bridging | ≥ 2,00 mm |

| Elongation at Break | ≥ %2000 |

| Fire Reaction Class | E |

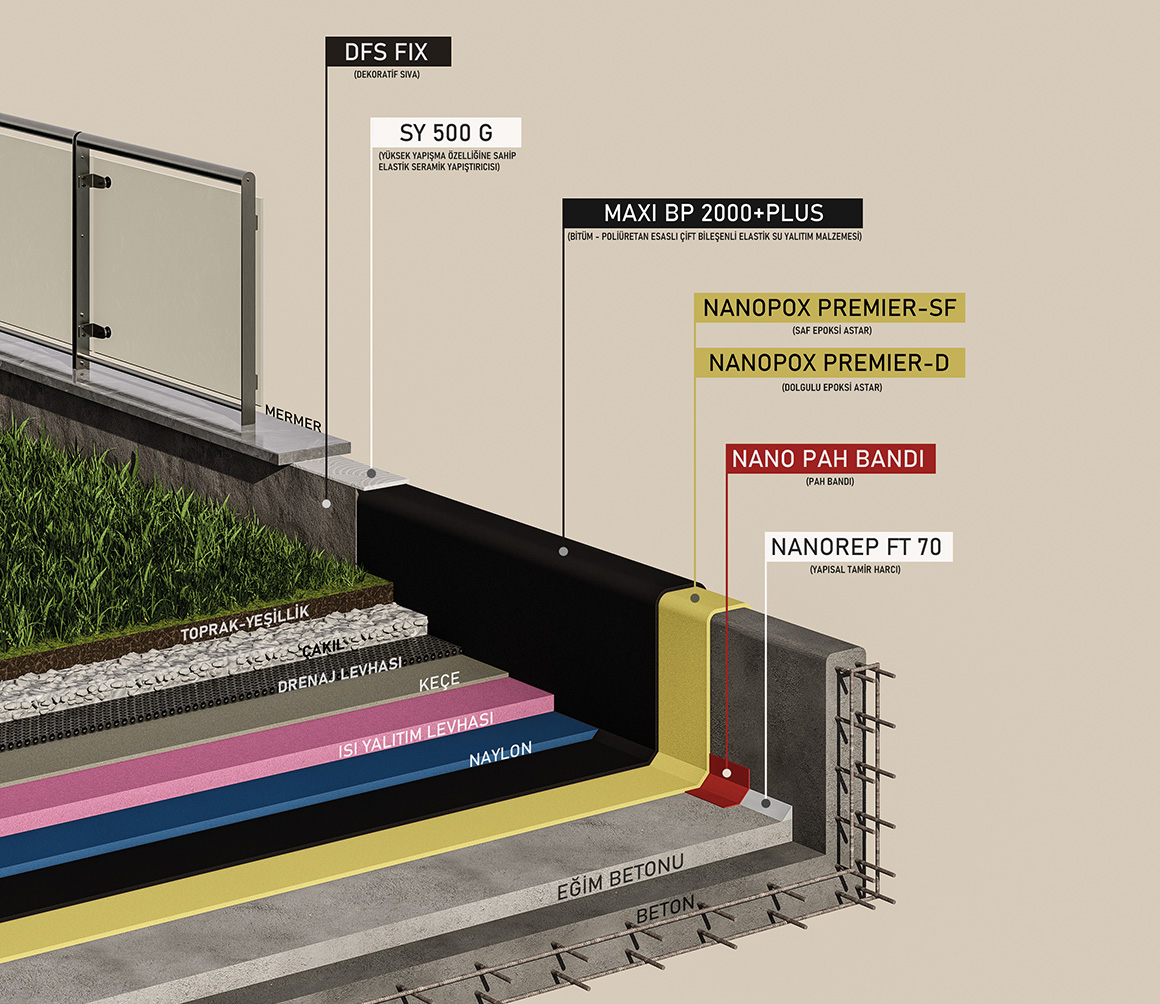

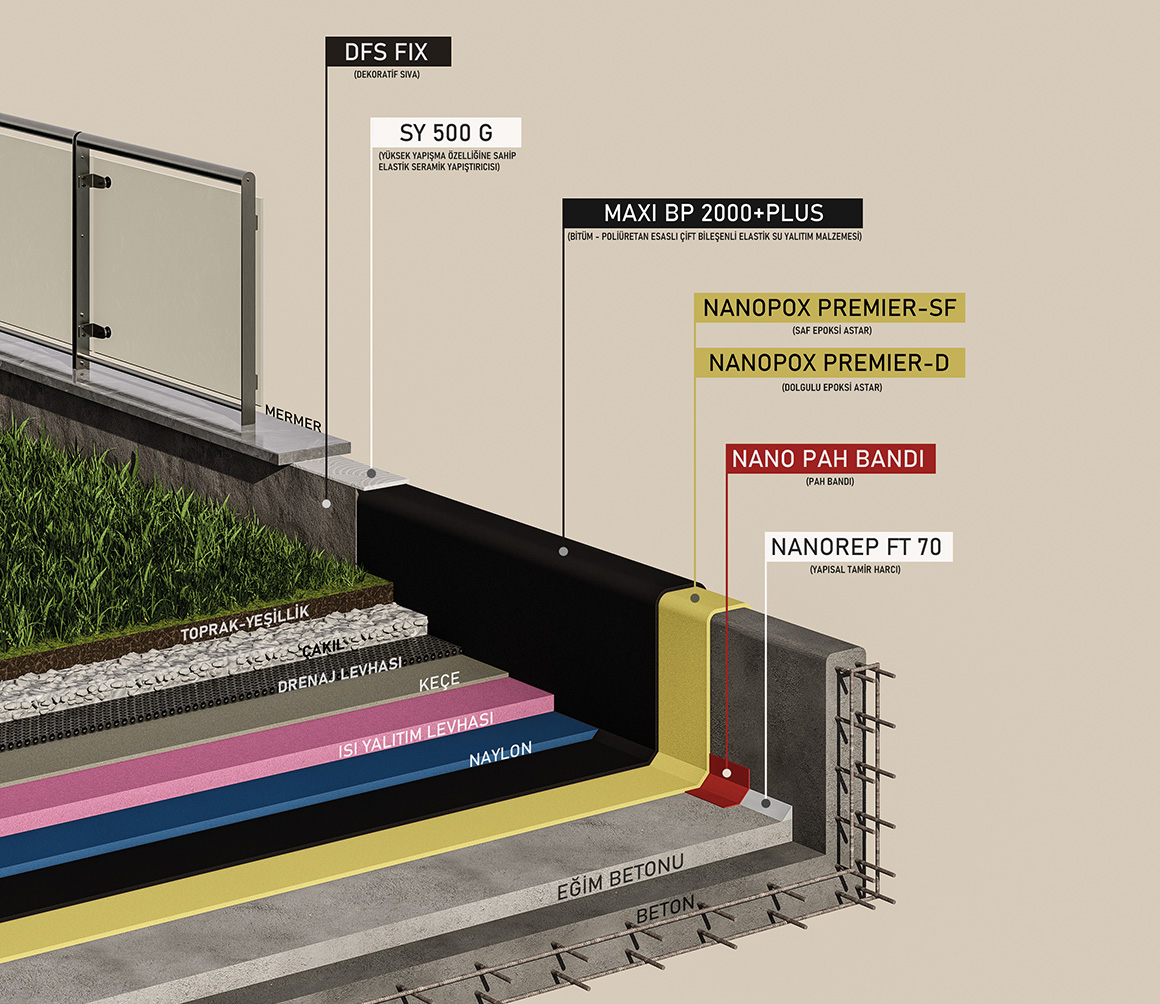

In green roof/terrace applications, parking deck waterproofing, foundation waterproofing, and under-coating waterproofing.

Component A: 20 kg Metal Bucket Component B: 20 kg Metal Bucket A+B Set: 40 kg Should be stored in its original packaging in a dry environment between +5°C and +35°C. In unopened packaging, it has a shelf life of at least twelve months when stored in a dry, cool, and closed place.

During application and mixing, contact with skin and eyes should be prevented. In case of contact, wash thoroughly with water. In case of eye contact, rinse immediately with plenty of water and seek medical attention. Gloves, protective clothing, mask, and goggles should be used during application

Before application, the surface should be checked, and if there are areas requiring repair, these should be fixed with NANOREP FT-70/30 series repair mortars. After this process, the waterproofing application should be carried out after 7 days. The surface must have at least 25 N/mm² compressive strength and at least 1.50 N/mm² pull-off strength. Prior to application, the surface should be primed with NANOPUR-NANOPOX series primers, depending on the roughness and absorbency of the surface. If necessary, two layers of primer can be applied. Under all conditions, the moisture content of the surface to be applied must be between 4% and 6%. Absorbent surfaces like cement-based and wood, as well as glass, metal, old ceramics, and bitumen-coated surfaces, should be primed with the NANOPUR SERIES. The primer consumption varies depending on the quality and absorbency of the concrete. It must be ensured that the primer has fully cured and hardened. After priming, the waterproofing should be applied between 4 and 48 hours. It should not be applied to fresh concrete surfaces. All drainage areas, gutters, and filters should be isolated using sealing bands. The surface to be waterproofed must be dry. Before starting the application (at least one day before), MAXI BP 2000 PLUS should be brought to standard room conditions (23±2°C). Before and during the application of MAXI BP 2000 PLUS, work and worker safety regulations should be followed, and appropriate work clothing, glasses, and masks should be used. MAXI BP 2000 PLUS is supplied in ready-to-use sets according to the mixing ratio. Before mixing begins, ensure the material temperatures are between +15°C and +25°C. The B component should be mixed with a mechanical mixer at 300-400 rpm for 4-5 minutes until a homogeneous mixture is achieved, ensuring no air is trapped. Then, the entire B component should be poured into the A component, and it should be ensured that no material remains in the B component. After A and B components are mixed thoroughly (at least 4-5 minutes), the mixture should be ready for use. The mixture should be applied to the surface with a stiff-bristled brush or spraying equipment. After the material has completed its reaction, the second coat should be applied perpendicular to the first coat. The waiting time between coats is at least 12 hours. After the first coat is applied, the other layers can be applied once no finger marks remain when checked by hand. Fine cracks, joints, corners, and edges should be reinforced with geotextile fabric after the first coat. In terrace roofs and similar applications, geotextile fabric should be applied to the entire surface after the first coat. After the coating is completed, the surface should not be exposed to direct water contact for at least 36-48 hours, and the air temperature should not drop below +8°C.