UV resistant, 1000% elastic, polymer-modified, bitumen-rubber based elastic

waterproofing product

It is a UV-resistant, 1000% elastic, polymer-modified, bitumen-rubber based,

single-component, highly elastic waterproofing material. It is used to

protect structural elements located underground, at ground level, or buried in soil

against the harmful effects of water. Suitable for use only on the

positive side. It can be applied to all mineral-based surfaces. It is resistant to

seawater and underground chemicals. It provides excellent adhesion to

all mineral-based surfaces. When applied, it forms a seamless waterproofing layer. It is

suitable for use against moisture, seepage water, and continuously pressurized water on

both horizontal and vertical structural elements that are constantly in contact with

soil and water. Once cured, it becomes

highly flexible and bridges shrinkage cracks. It can be easily applied with a brush or

trowel. It has high aging resistance under exposed conditions and

is resistant to water, various salt solutions, soil chemicals, and weak acids. It can be

safely used on surfaces exposed to movement and vibration. It

can be easily applied with a brush, trowel, or spray machine. It is solvent-free and

environmentally friendly.

General Characteristics

Can be used on all mineral-based surfaces, has high adhesion. UV

resistant. Highly elastic. Can be applied on fresh concrete and damp

surfaces. Resistant to salt solutions and mild acids. Resistant to freezethaw cycles.

Forms a seamless, monolithic waterproofing layer. Easily

applied with brush, trowel, or spray machine.

| Relevant Standard | EN 15814 |

|---|---|

| Product Class | CB2W1AR1 |

| Certificate Number | 2163-CPR-1091 |

| Application Temperature | (+5) - (+35)0°C |

| Product System | Bitüm-Kauçuk |

| Public Works Item No. | 10.300.2176 |

| Service Temperature | (-40) - (+80)0°C |

| Density (kg/m³) | 1,10±0,03 |

| Consumption | 1.00 – 1.50 kg/m² (1 mm thickness) |

| Consistency | Trowel Consistency |

|---|---|

| Initial Drying Time (at 20 °C) | 6±1 hours |

| Waiting Time Between Coats | 1 – 2 hours |

| Full Curing Time | 1 – 5 day |

| Time to Service | 7 day |

| Crack Bridging Ability | Class CB2 (2 mm) |

| Water Impermeability | Class W1 (3 mm) |

| Reaction to Fire Class | E |

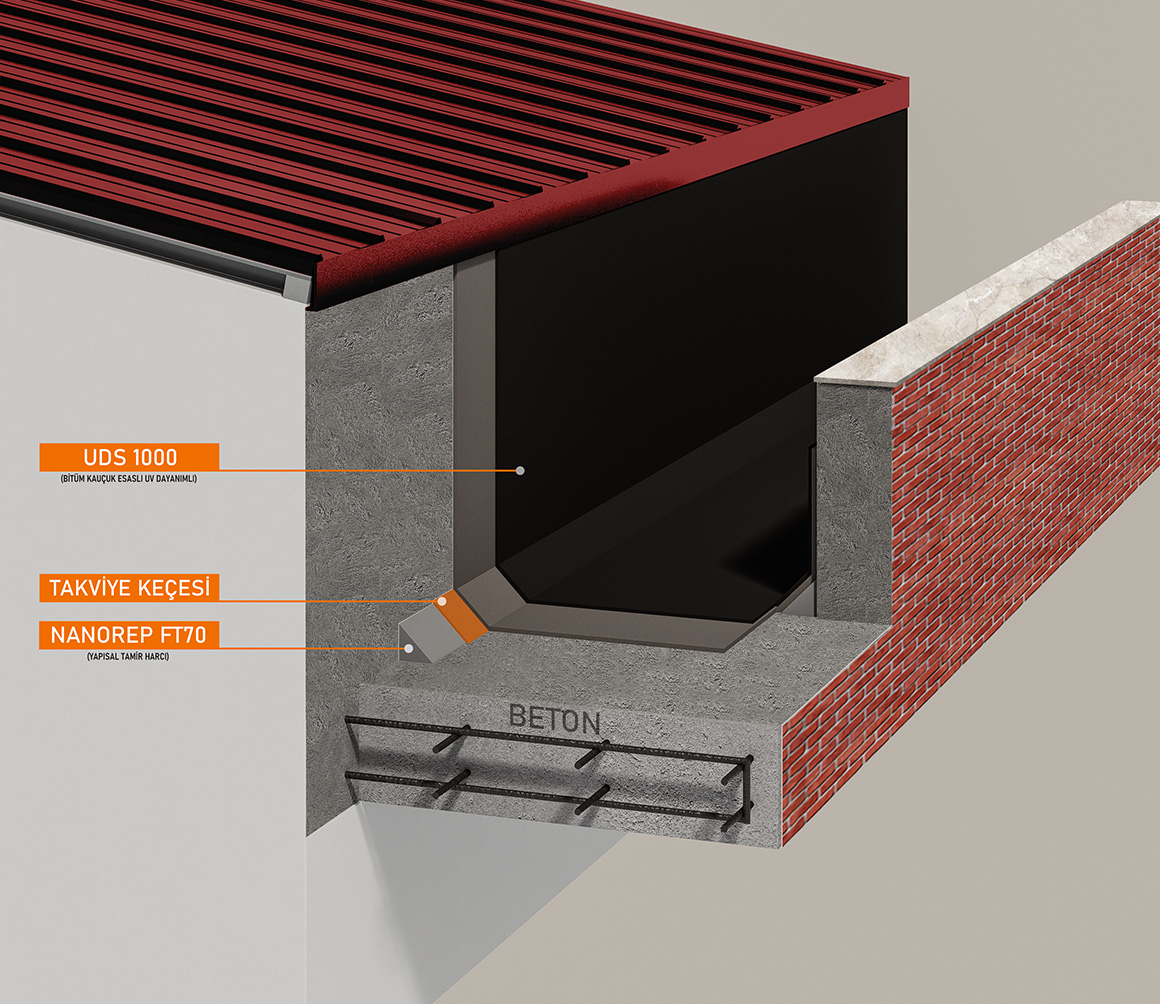

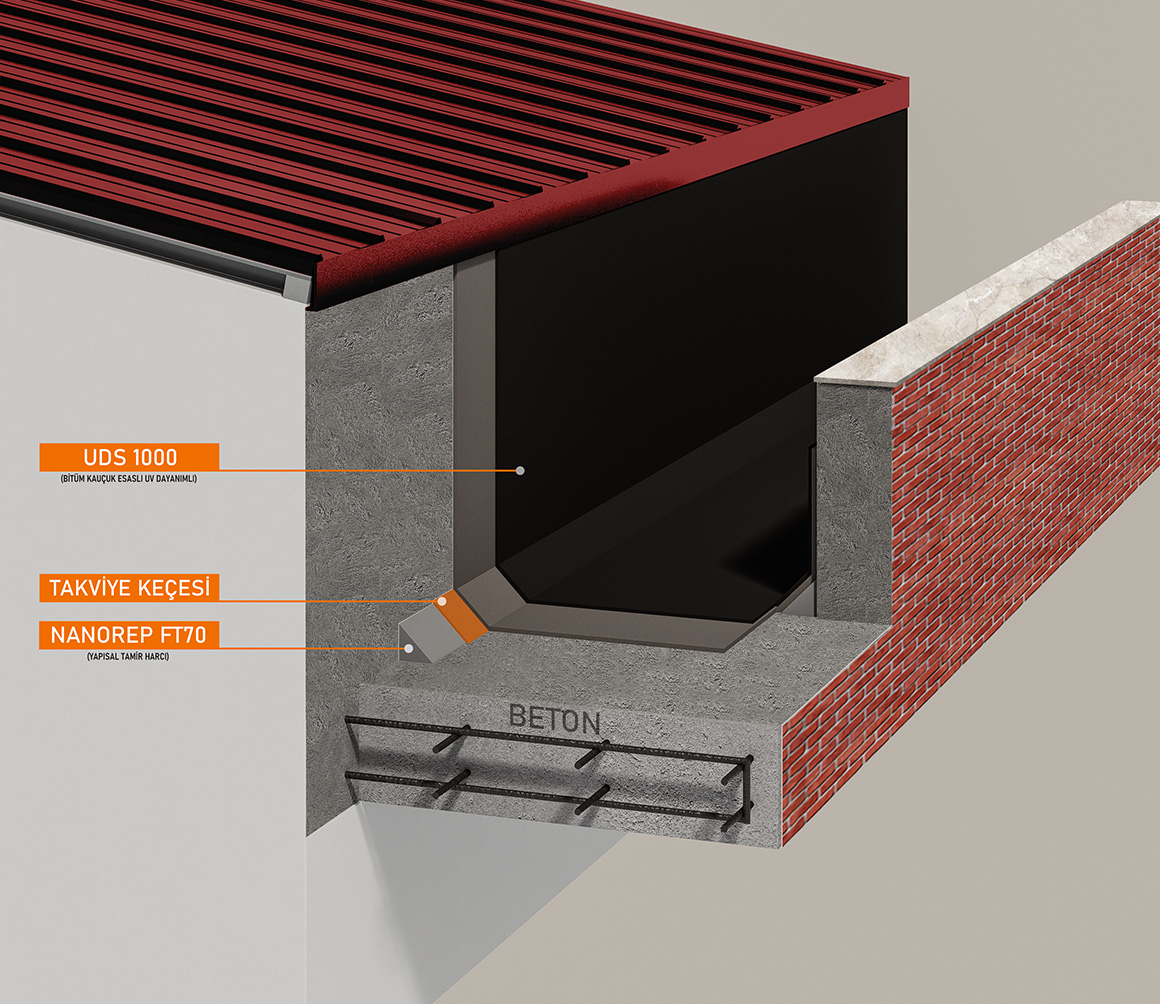

• In the waterproofing of sloped roof gutters, • In the renovation of shingle-sanded membranes, • In foundation waterproofing, • In the waterproofing of sloped, non-walkable terraces, • On reinforced concrete, panel, and similar surfaces exposed to sunlight

20 kg Plastic Bucket It should be stored in its original packaging in a dry environment between +5°C and +35°C. In its unopened packaging, it has a shelf life of at least twelve months in a dry, cool, and enclosed area.

During application and mixing, contact of the material with skin and eyes should be avoided. In case of contact, rinse thoroughly with plenty of water. If it comes into contact with eyes, rinse immediately with plenty of water and seek medical advice. Gloves, protective clothing, mask, and goggles should be used during application.

The surface to be applied should be solid, dry, clean, and free from loose particles. Deep voids on the surface should be filled with repair mortar. Internal corners and wall joints should be chamfered. The surface to be applied should be primed with a solvent-free bitumen primer, and application should be carried out only after the primer has fully dried. The product can be diluted at a ratio of 1/5 for priming. The material should be evenly spread with an appropriate brush and applied on horizontal surfaces without allowing any material buildup. The primer should be allowed to dry before proceeding with the main application. A usage rate of 0.25 kg/m² is recommended. The prepared surface should be applied in at least two coats using a brush, trowel, or spray. After the first coat is applied, the second coat should be applied only after the first coat has fully dried. The second coat should be applied perpendicular to the first coat. It is suitable for use with elastic reinforcement in both sloped and flat large areas. When the first coat (1.5 kg/m²) begins to set, the elastic reinforcement is spread over the surface. After making the necessary detail cuts, the second and third coats (1.5 kg/m² each) should be applied.