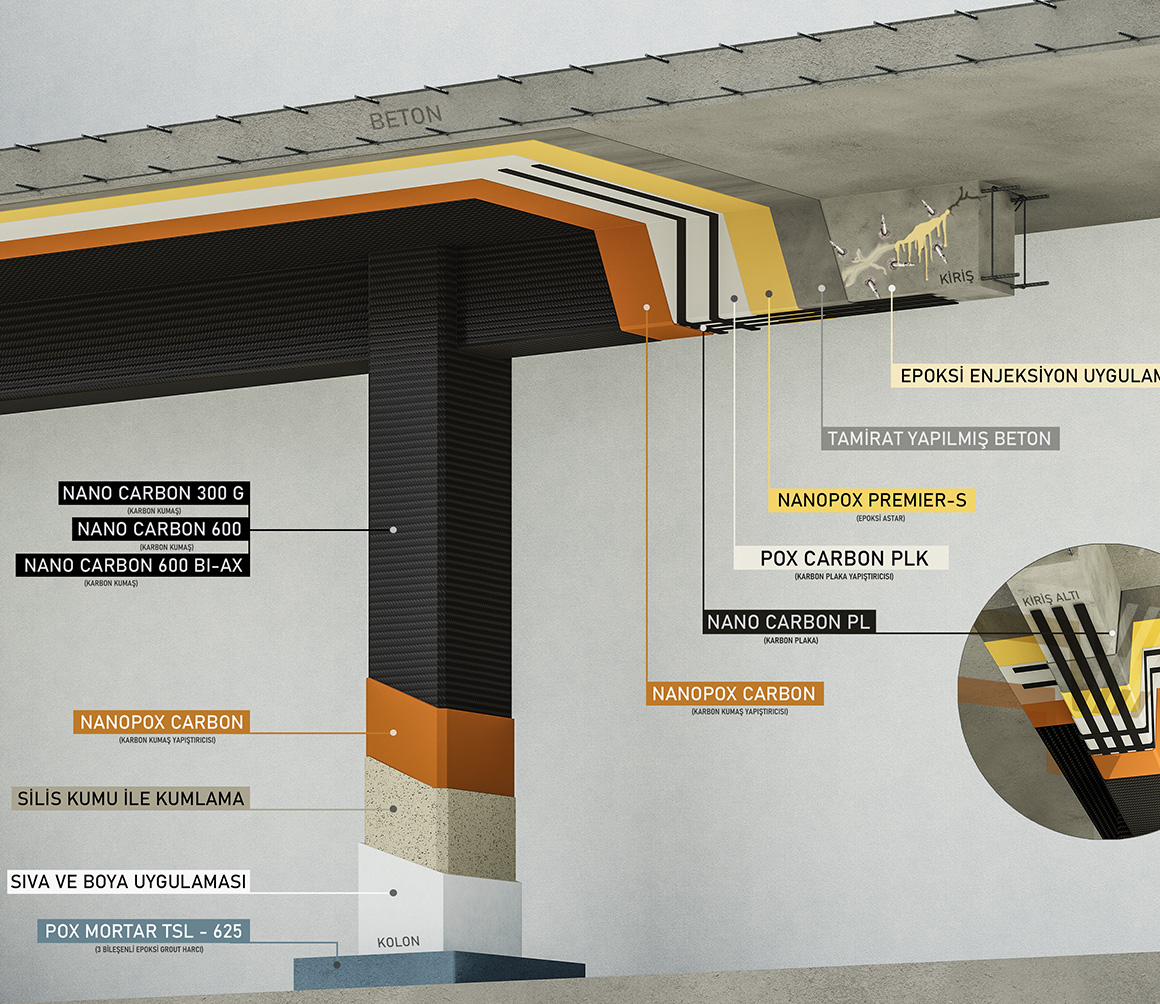

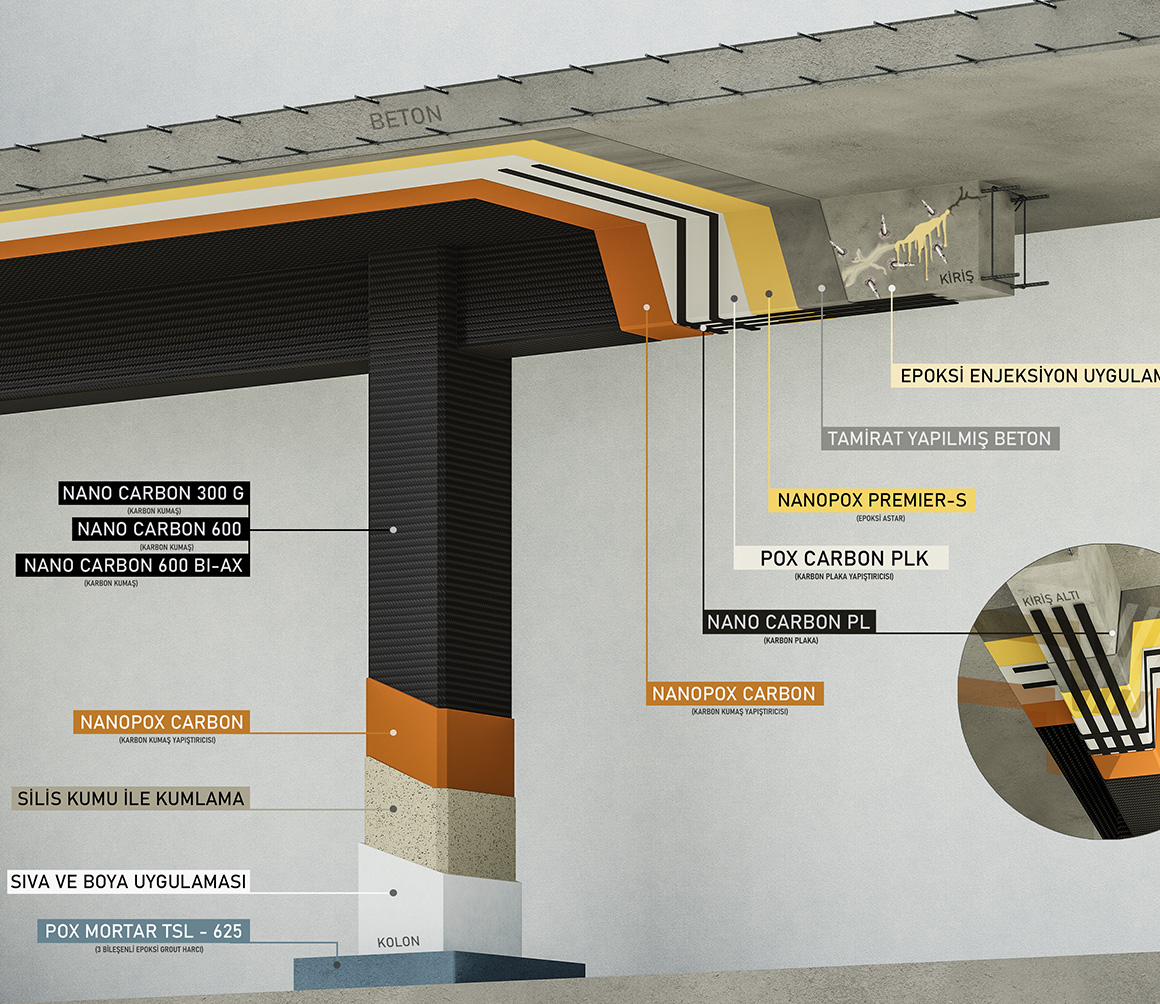

Epoxy-based, two-component carbon plate adhesive.

It is a two-component, solvent-free, thixotropic epoxy-based carbon plate adhesive

General Characteristics

It is a two-component, solvent-free, epoxy resin-based, thixotropic

adhesive and repair paste specially developed for bonding carbon

reinforcement plates. It can work on vertical surfaces without sagging. It

is a very easy-to-apply material. It is impermeable to water and gas. It is

used on vertical and overhead surfaces. It is resistant to chemicals and

abrasion. It adheres excellently to concrete, wood, and steel. It has high

mechanical properties. It does not contain solvents.

| Specific Gravity | 1.75 g/cm³ (A+B) |

|---|---|

| Color | Gray |

| Application Temperature | +10°C / +35°C |

| Adhesion to Concrete | 4 N/mm2 (28 days, 20°C) |

| Compressive Strength | 90N/mm2 (7 days, 20°C) |

|---|---|

| Flexural Strength | 25 N/mm2 (7 dayws, 20°C) |

| Full Curing Time | 7 Gün |

| Mixing Ratio | 1:1 |

It is used for bonding carbon plate materials. It is used for the repair and bonding of all types of materials such as concrete, stone, marble, and for plate bonding in beam and deck repair and reinforcement.

5 kg set (3.75 kg (A) + 1.25 kg (B)). When stored in its original packaging in ventilated, dry, and protected environments at +10°C / +30°C, and protected from sun, rain, and freezing, the shelf life is 1 year from the production date.

During application and mixing, contact with skin and eyes should be prevented. In case of contact, wash immediately with plenty of water. If it comes into contact with the eyes, rinse immediately with plenty of water and seek medical help. Gloves, protective clothing, mask, and goggles should be worn during use.

Surface Preparation: The application surface must be free from dust, dirt, weak and loose particles, cement slurry residues, oils, and grease, and should be dry. The concrete substrate should be clean, solid, and have sufficient compressive strength (at least 25 N/mm²) and tensile strength (pull-off) of at least 1.5 N/mm². The application surface should be cleaned using methods like compressed air to achieve the highest adhesion strength. Weak concrete parts should be broken and repaired with high-strength repair mortar to restore them to their original condition. Mixing: After component B is added to component A, it should be mixed with a low-speed electric mixer (maximum 300 rpm) for 2-3 minutes until a homogeneous color is achieved. Application: In extremely hot weather, the product will harden immediately once mixed, so only enough mixture for immediate use should be prepared. It should not be applied if the temperature is below +5°C. POX CARBON-PLK epoxy paste is applied to the concrete surface with a spatula or roller. Carbon plates are then applied to the surface, ensuring no air gaps remain. While doing this, a roller or cylinder should be used to push the excess paste outwards. The same procedure should be applied to the entire surface, ensuring that the epoxy paste covers the top surface homogeneously.