Epoxy-based, two-component carbon fabric adhesive.

It is a two-component, solvent-free, thixotropic, epoxy-based impregnation resin and

adhesive.

General Characteristics

It is easy to mix and easy to apply with a spatula or filling roller. It is intended

for manual filling. It has high mechanical strength. It is applied on vertical

and overhead surfaces. It provides good adhesion to many surfaces. It has

high mechanical properties. No separate primer application is required.

It is solvent-free.

| Specific Gravity | 1.43 kg/lt (A+B) |

|---|---|

| Color | Orange |

| Viscosity | 200-500 MPa.s |

| Application Temperature | +5°C / +35°C Flash Point +65°C |

| Adhesion to Concrete | 4 N/mm2 (28 days, 20°C) |

| Compressive Strength | 70 N/mm2 (7 days, 20°C) |

|---|---|

| Flexural Strength | 25 N/mm2 (7 days, 20°C) |

| Full Curing Time | 7 days |

| Mixing Ratio | 4:1 |

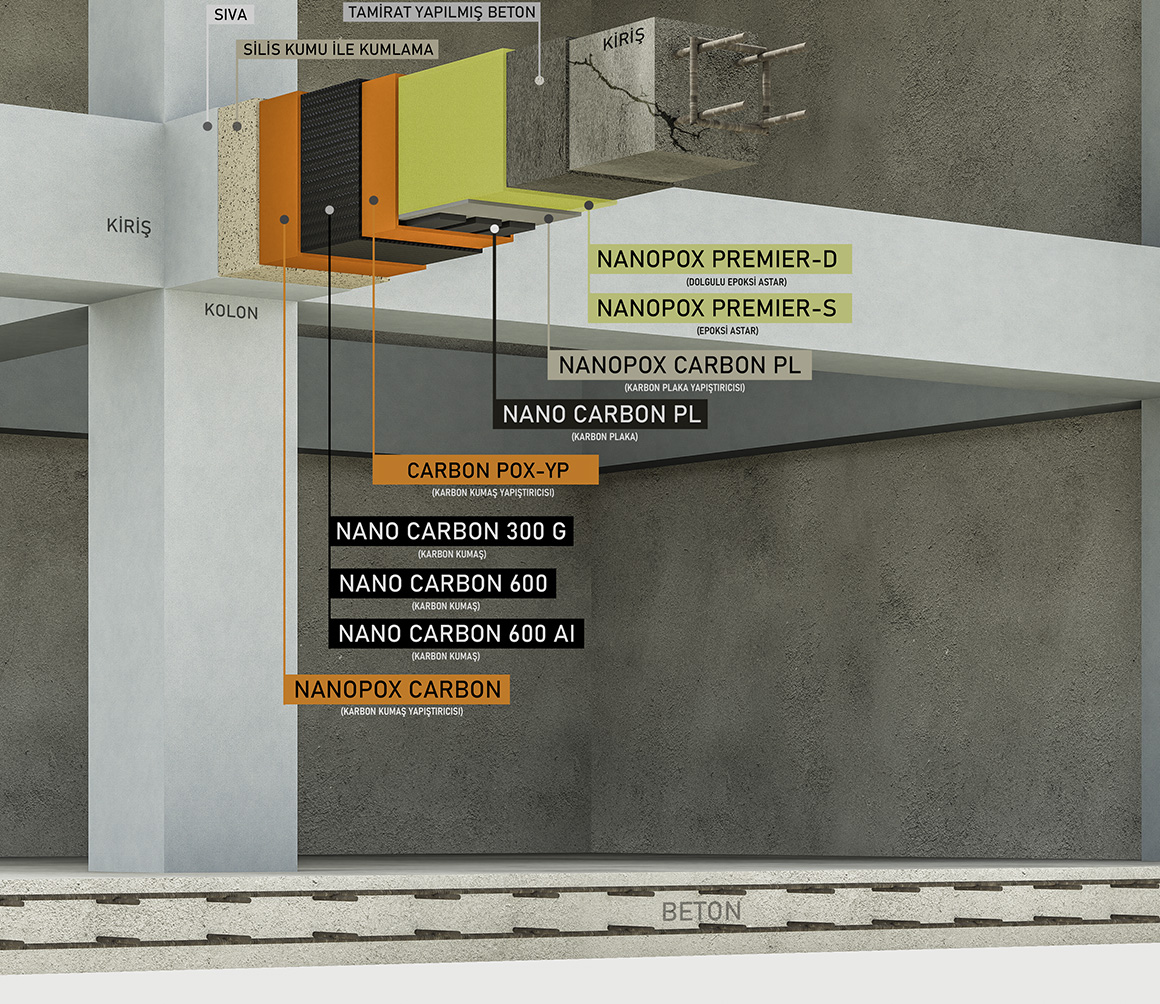

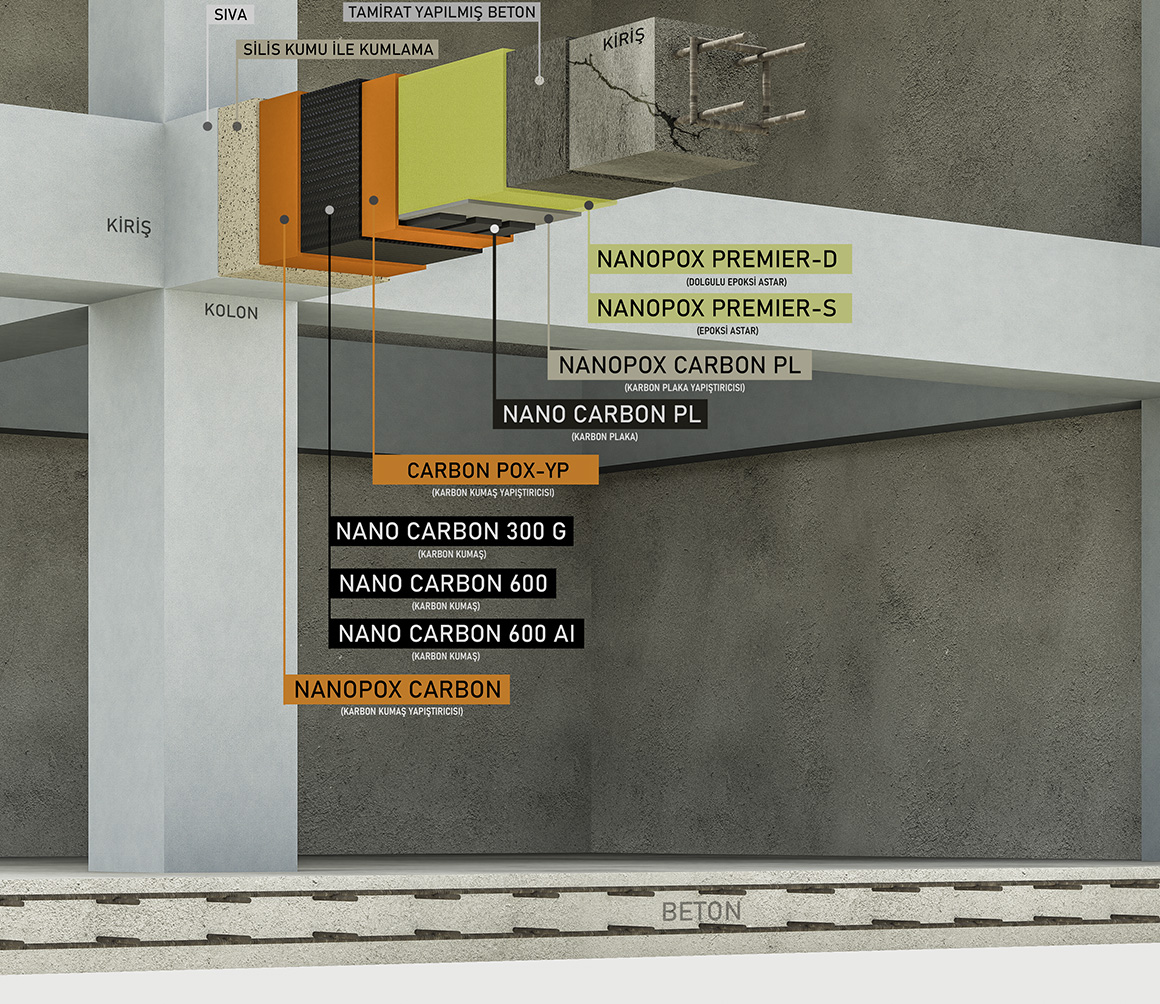

It is used for the wrapping and bonding of damaged concrete, columns, walls, beams, and other structural elements with carbon fabric. It is used in stone and solid brick, reinforced concrete strengthening, and fabric applications

4 kg set (4 kg (A) + 1 kg (B)) In its original packaging, when stored in a ventilated, dry, and protected environment at +5°C / +25°C, protected from sunlight, rain, and frost, the shelf life is 1 year from the production date.

During application and mixing, contact of the material with skin and eyes should be avoided. In case of contact, rinse thoroughly with plenty of water. If it comes into contact with eyes, rinse immediately with plenty of water and seek medical attention. Gloves, protective clothing, mask, and goggles must be worn during use.

Surface Preparation: The application surface must be free from all kinds of dust, dirt, weak and loose particles, cement laitance residues, oil, and grease, and must be dry. The concrete substrate must be clean, sound, and have sufficient compressive strength (at least 25 N/ mm²), and the pull-off strength must be at least 1.5 N/mm². To ensure maximum adhesion strength, the application surface must be cleaned using methods such as compressed air. Weak concrete parts must be removed and repaired with high-strength repair mortar to restore to its original state. Mixing: After adding component B into component A, it should be mixed for 2-3 minutes with a low-speed electric mixer (maximum 400 rpm) until a homogeneous color is obtained. Application: NANOCARBON 300G/600GMU/600BI-AX should be cut and prepared according to the area to be applied. The prepared CARBON POX-YP mixture is applied onto the concrete with a spatula or roller. Then, NANOCARBON 300G/600GMU/600BI-AX is placed on top and adhered by hand to ensure the epoxy bonds well to the carbon. During bonding, a lightly serrated plastic roller is used to press out the excess epoxy. This process should be applied evenly across the entire surface to ensure the epoxy comes out on the upper surface. If the epoxy is insufficient, CARBON POX-YP should be applied again to saturate the carbon fibers. Carbon fibers are non-combustible, but epoxy may ignite after a certain temperature. Therefore, after applying a very thin layer of epoxy on the carbon fiber, dry sand is sprinkled on top, and plaster is applied over it. The sprinkled sand ensures adhesion between the carbon fiber and the plaster.